As you can see on the picture below there is a lot of room between the seat pipes and the rear axle. I had a problem with shocks not being stock height. After I adjusted the front forks down it raised the rear end about 2.5". Again this is why I used conduit for mocking it up. So needless to say all this needs to be readjusted. I will hold off until I score a pair of stock shocks.

|

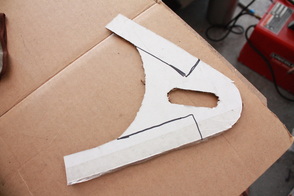

So I began working on the mock up for the rear hard tail. I decided to use 1" electrical conduit piping to get the practice on for bending, cutting, and tack welding to mock up how I want the final frame and bends to be. The pipe is great to work with because it is MUCH cheaper and forgiving. Plus once I am happy with it, they will serve as guides for running my actual pipe for the frame. As you can see on the picture below there is a lot of room between the seat pipes and the rear axle. I had a problem with shocks not being stock height. After I adjusted the front forks down it raised the rear end about 2.5". Again this is why I used conduit for mocking it up. So needless to say all this needs to be readjusted. I will hold off until I score a pair of stock shocks. The tough trick is getting the axle placement exactly where I want it. Once that is located then I welded the swingarm in place so that it won't move. This will allow me to put my axle plates (cardboard cut outs currently) on. See below. Once I have the axle plates in place then I can get the piping measurements exact and cut and tack weld them on. Hopefully I will be getting some 3/8" plate steel this week then plasma cut the axle plates and clean 'em up to put on here. I learned when I was a kid to measure twice and cut once. I am learning as an adult to measure 27 times and cut 3 times, grind some, grind some more and then you are close.

0 Comments

Leave a Reply. |

YAMAHA

|

RSS Feed

RSS Feed