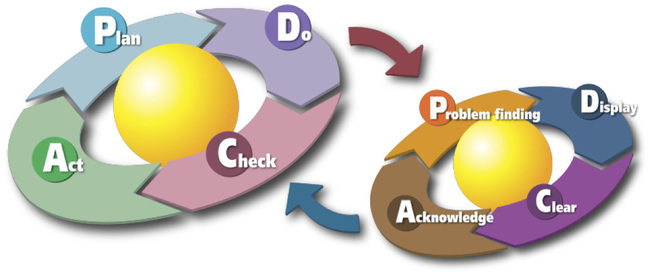

3000 ideas per day... or better yet, one million ideas per year is the amount of new ideas that Toyota implements per year. This explains why Toyota seems to be on a different playing field of their own. The truth is it is not about the cars. It is all about the ideas and the people with those ideas. Kaizen is all about small ideas, small improvements. These are not necessarily touchdowns after a 99-yard run but 2.5 yards every play over and over again to win the game. It is born of excellence.

Althought Toyota in today's view is not the most positive because of some of the recent safety issues, they led the way for many years. Why is Toyota worth almost as much as all the auto builders combined? The human element, the one resource that is the pinnacle of human creativity and participation. This pursuit of excellence is almost a taste of blood for perfection. The true meaning of Kaizen - continuous improvement. How does a guy, after World War II, W. Edwards Deming, change Japan and make them a leader of proficiency? Through the eyes of the ant, small but powerful workers that are all doing their own part to make the entire culture the most synergistic machine possible. The synergy that says the sum is greater than any measurement of the individuals.

The following information is also available more thoroughly here.

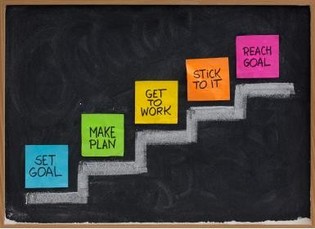

Kaizen mindset rules. Every company employee is encouraged to come up with ideas – however small – that could improve his/her particular job activity, job environment or any company process for that matter. The employees are also encouraged to implement their ideas as small changes can be done by the worker him or herself with very little investment of time.

Quick and Easy Kaizen helps eliminate or reduce wastes, promotes personal growth of employees and the company, provides guidance for employees, and serves as a barometer of leadership. Each Kaizen may be small, but the cumulative effect is tremendous.

In simpler terms... good enough never is!

RSS Feed

RSS Feed